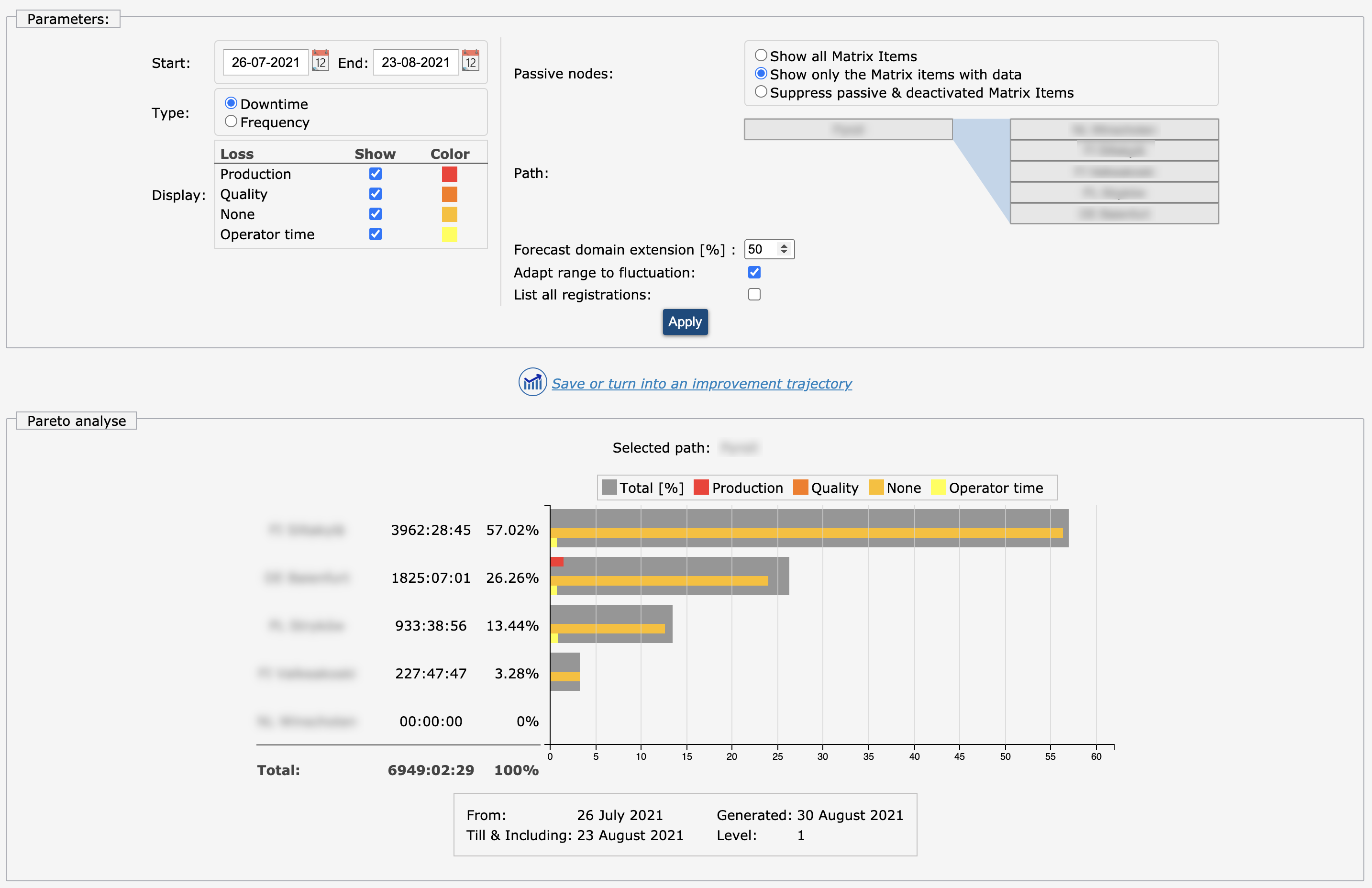

Durante l'analisi, il grafico di Pareto organizza l'albero dei guasti in base alla durata o alla frequenza degli eventi. Partendo dai livelli più elevati, il grafico a barre mostra chiaramente l'impatto in termini di tempi di inattività o di frequenza. Cliccando su una barra specifica, è possibile effettuare uno zoom per arrivare fino alla causa principale. Così il management può individuare facilmente i fermi di produzione e stabilire su quali aree intervenire per prime.

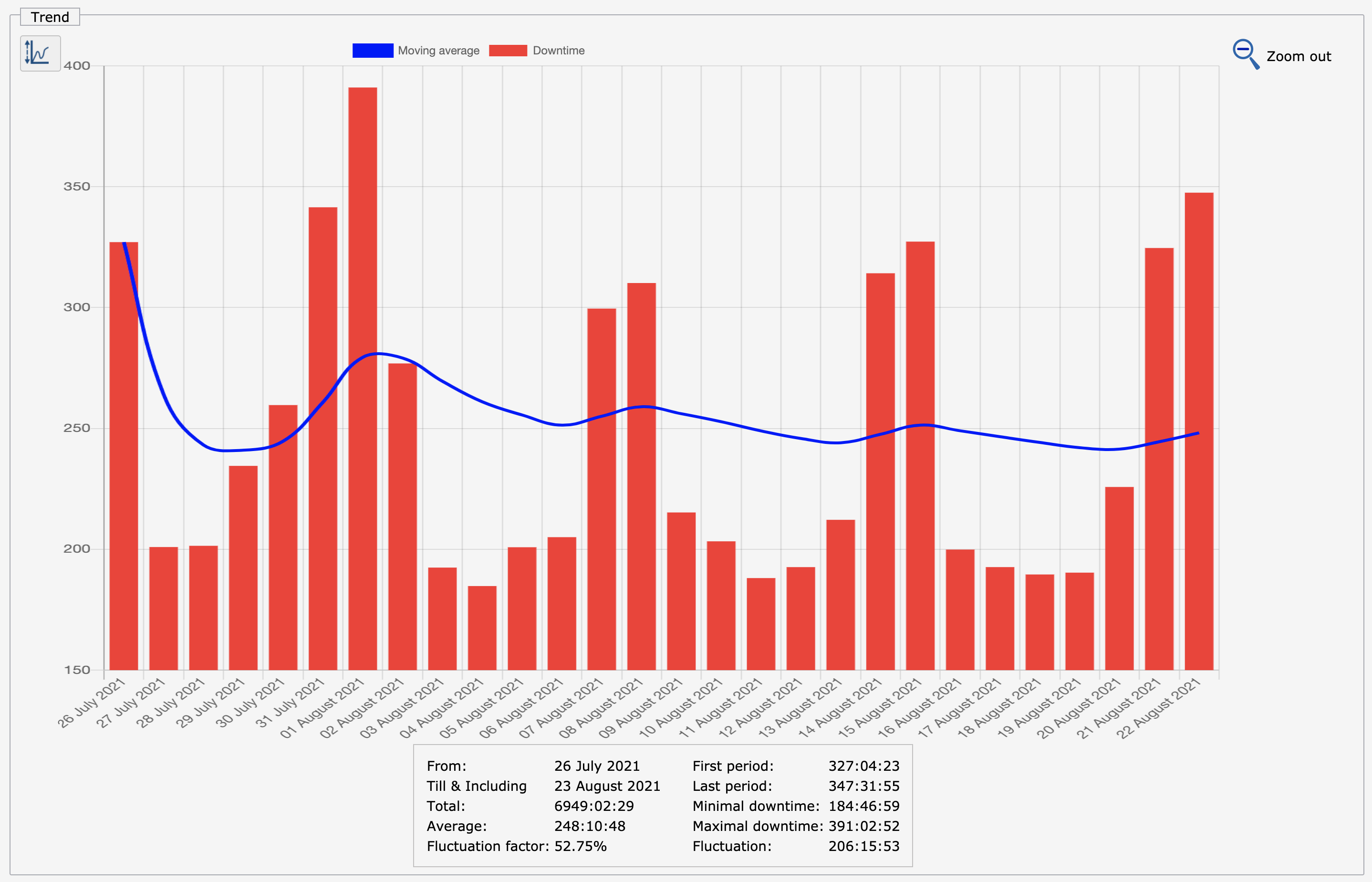

L'analisi delle tendenze illustra l'andamento dei tempi di inattività o della frequenza nel tempo, risultando utile per monitorare l'efficacia delle misure preventive. In molti casi, dopo l'implementazione di azioni correttive, si osserva inizialmente una tendenza al rialzo (forse dovuta a una maggiore attenzione al problema o al fenomeno Baader-Meinhof) prima che l'effetto desiderato si manifesti. Se, dopo un periodo di tempo, la tendenza al ribasso non si verifica, il management dovrà rivedere le proprie strategie.

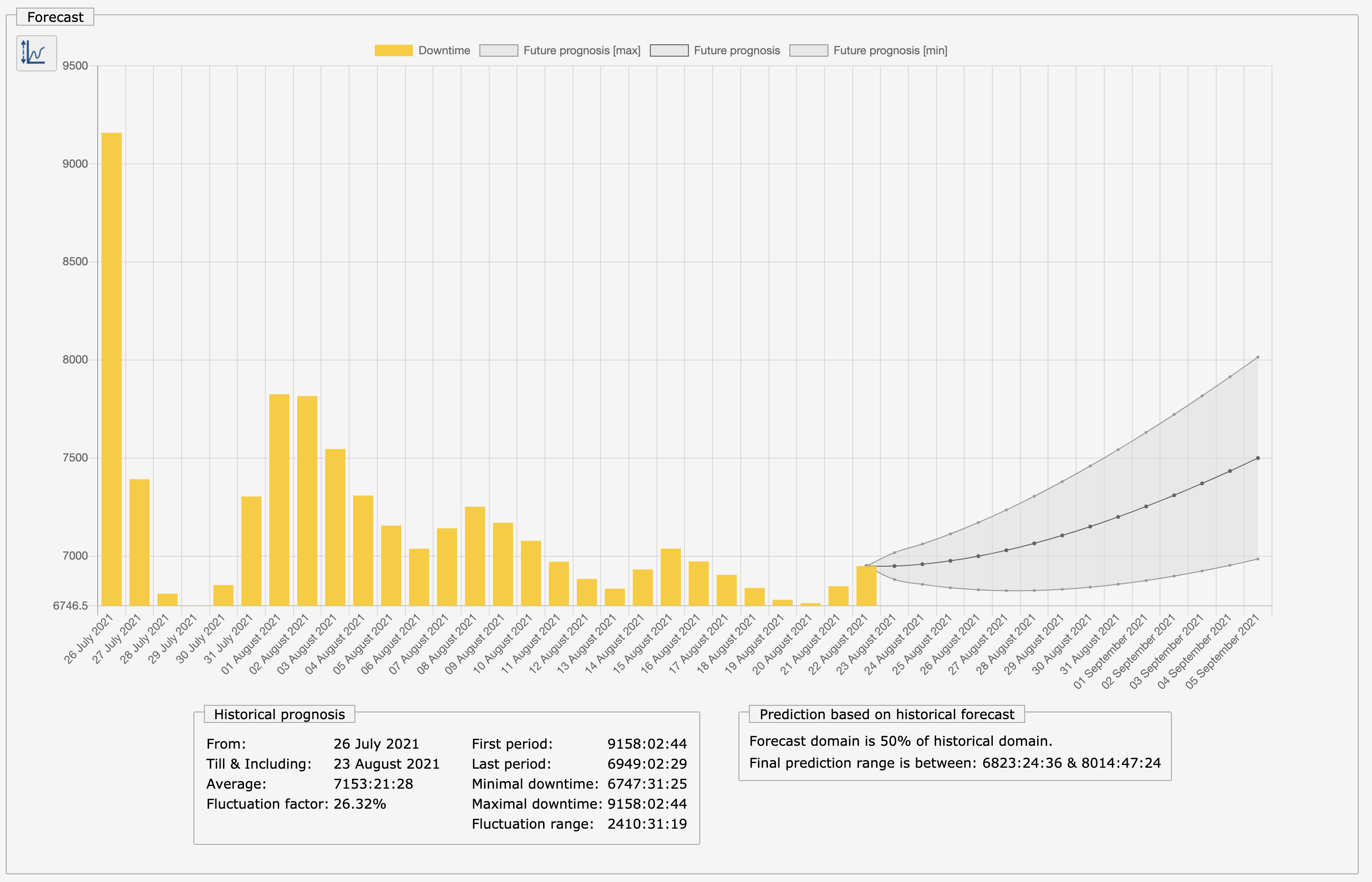

Il grafico di previsione, invece, aiuta a individuare i problemi in rapido sviluppo che, seppur attualmente contenuti, potrebbero aggravarsi se non si interviene tempestivamente.

Infine, l'analisi degli articoli per la gestione degli asset consente di generare report mirati su parti specifiche o su problematiche riscontrate nel processo produttivo o logistico.